Our Process

Our Origins

Office

Team Meeting

Fabrication

Site Installation

Office

It all starts here…

Taking a request to quote from something as simple as a hand sketched drawing to architectural plans. Our team will work through the process of working out what is required, drafting up shop drawings, planning and scheduling to get your job onto the workshop floor to be fabricated and then, if required, we send our team to install

Adam

Owner – Director, can work across all aspects of his business

Aain

Senior Estimator “Quite Achiever”

Luke

Senior Drafter & Detailer “Cool hand Luke”

Riley

Production Co-ordinator and currently training in Drafting & Detailing “King of Loud Shirt Day”

Sharon

Administration - wearer of many hats

Tim

Workshop Foreman - “Ask me why I’m called SAS”

Team Meeting

Regular meetings are held to bring our tribe together for updates.

Fabrication

Where your drawings go from raw materials to assemblies for installation.

Fabrication is more than just welding pieces of metal together. It is a science requiring calculations and measurements, knowledge of the medium you are working with, interpretation of drawings and execution of trade skills. Every piece of metal is cut to specific requirements and then shaped, welded, grinded and assembled by our workshop team into members that are then taken to site for installation.

Site Installation

Installation is not for the faint of heart. You need to like heights and confined spaces. But if you are good with that then you will work in some of the best views of Sydney basin

While having metal fabrication as a trade is important, we also require an installation team that has a great understanding of putting things together on building sites, it’s not just about welding metal together.

Our Origins - Adam's Story

Owning and building this business is more than a job for me. “Steel is in my blood.”

It’s a multi generation thing…

I’m a third generation and I now have 2 sons coming through learning the business as trade persons.

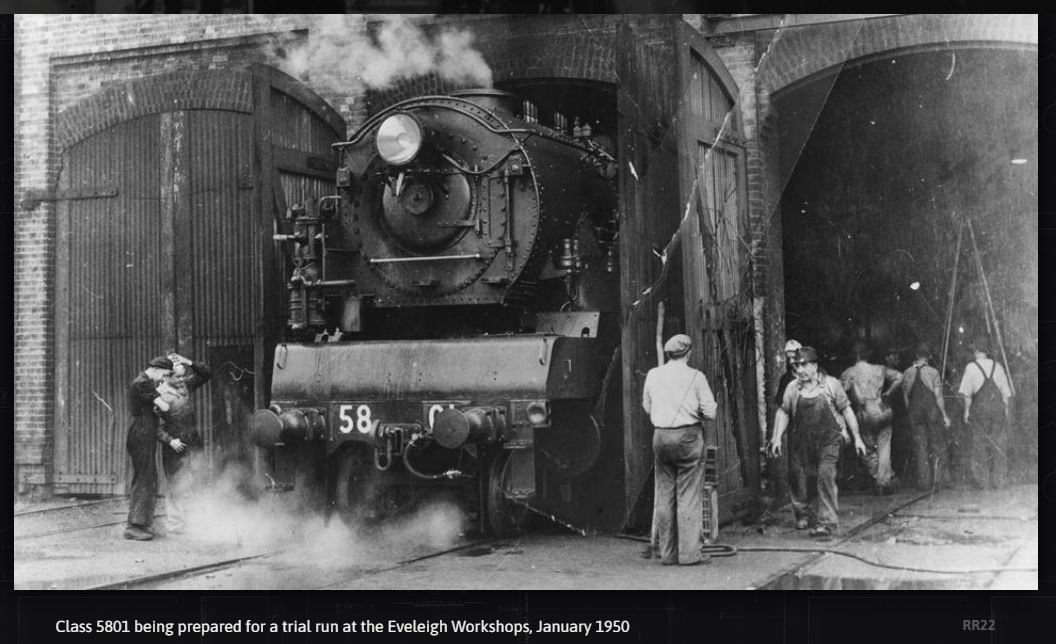

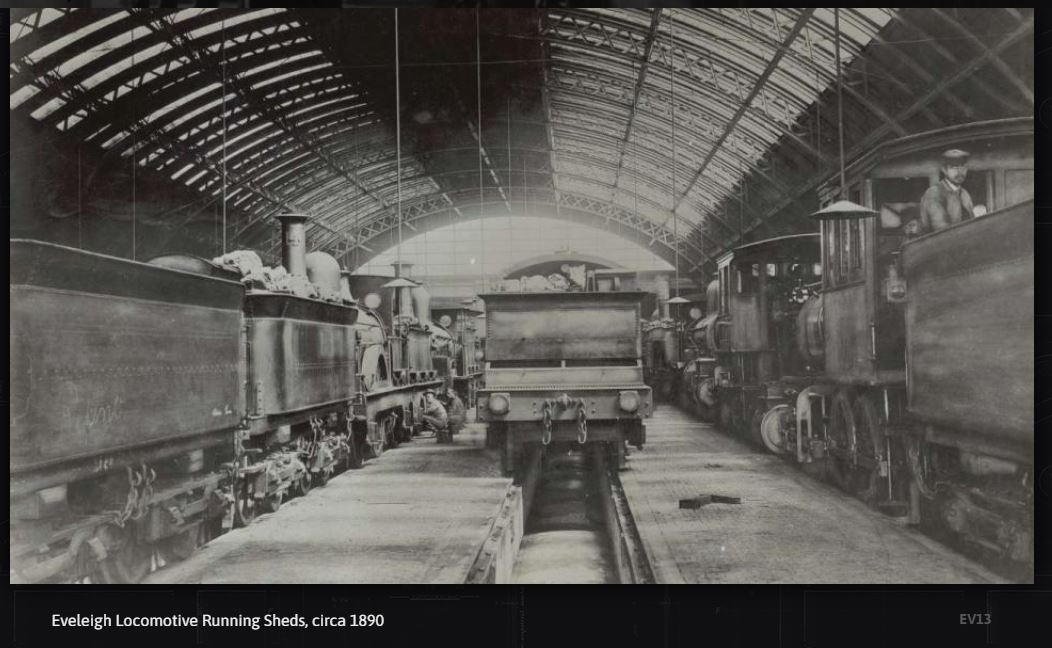

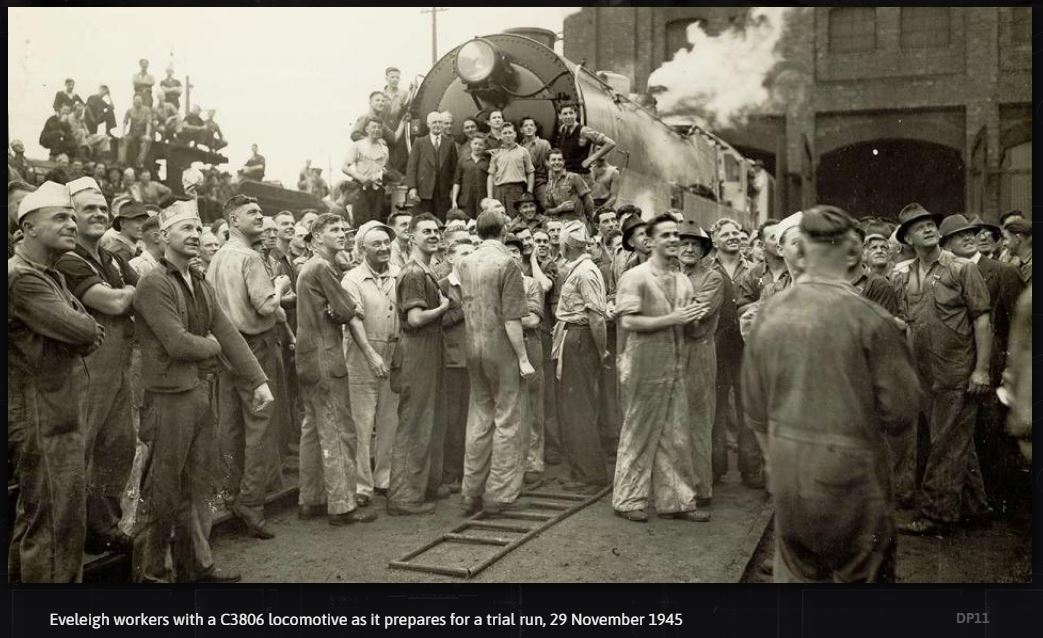

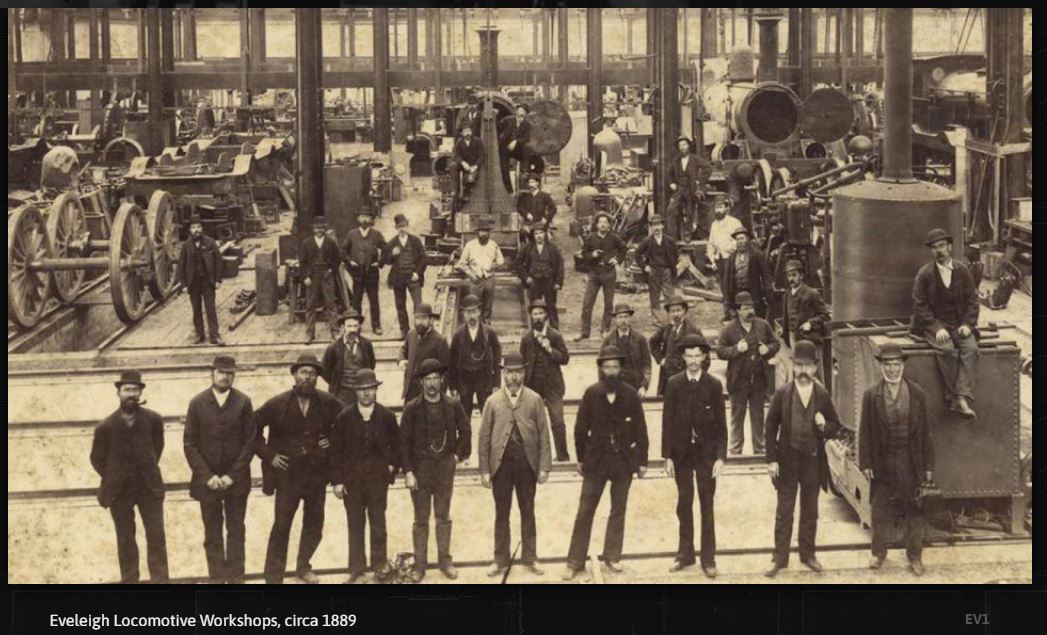

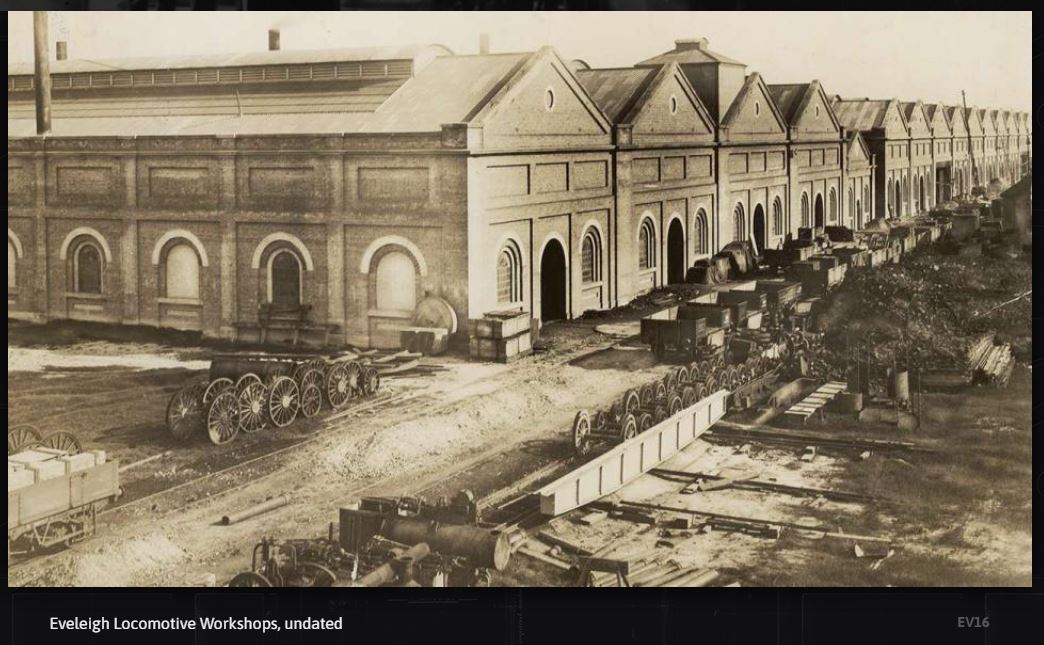

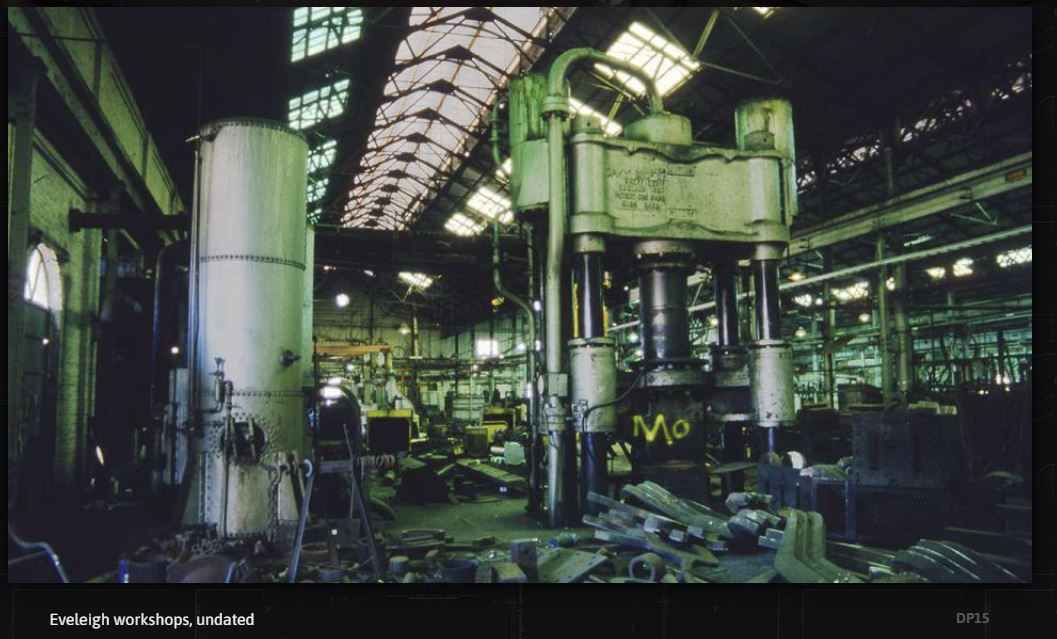

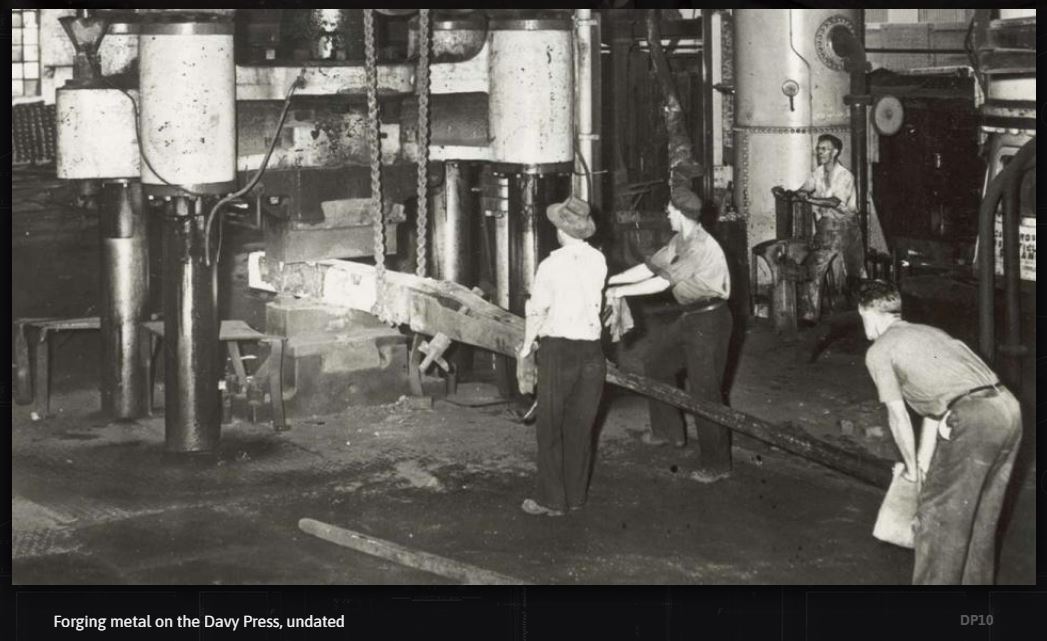

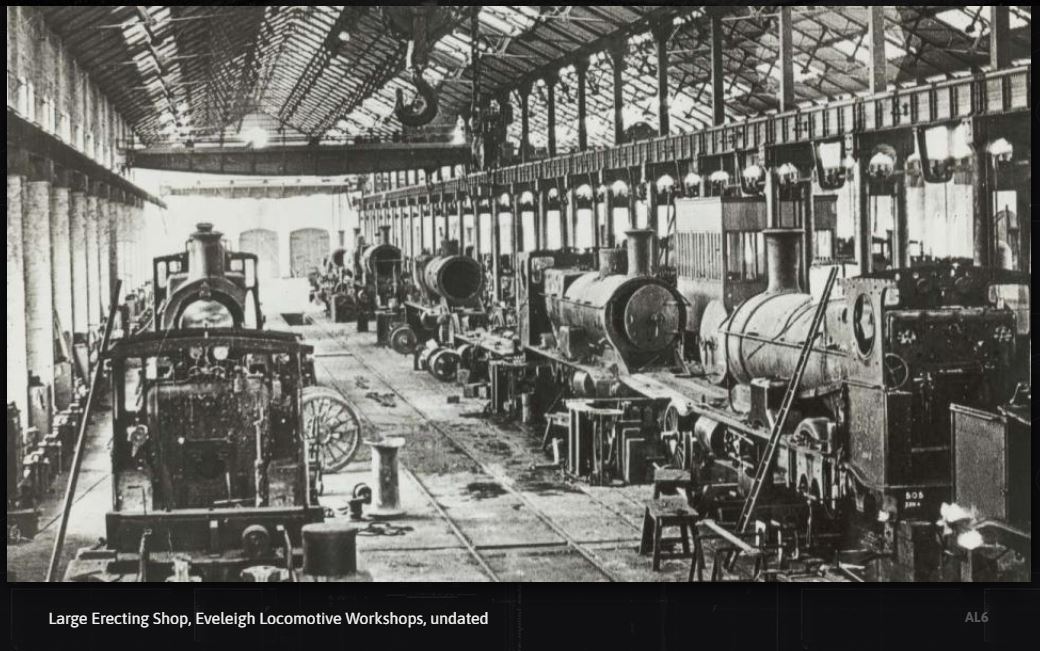

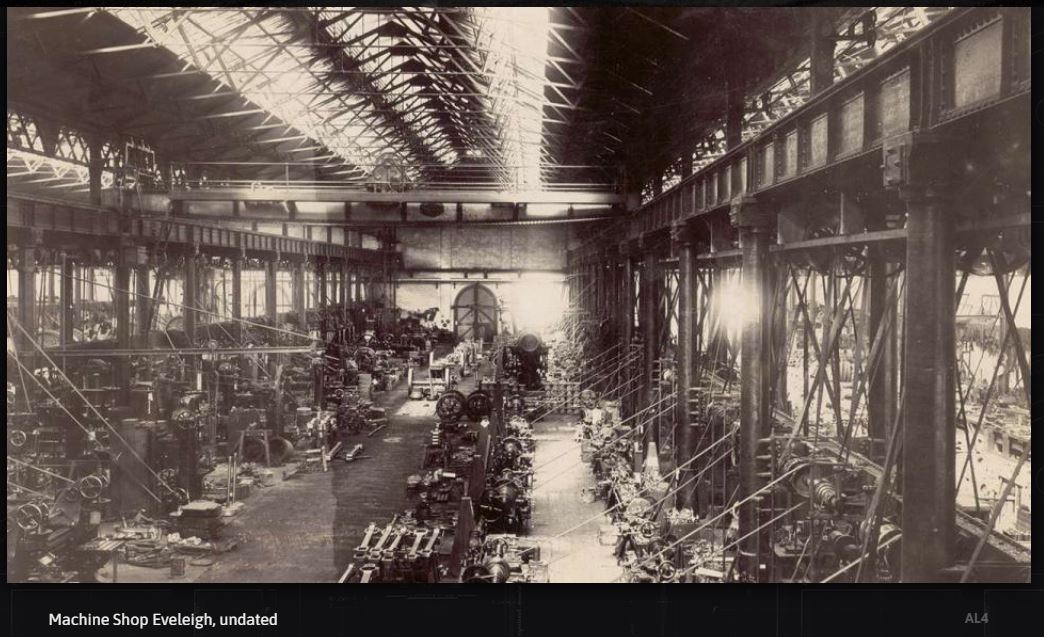

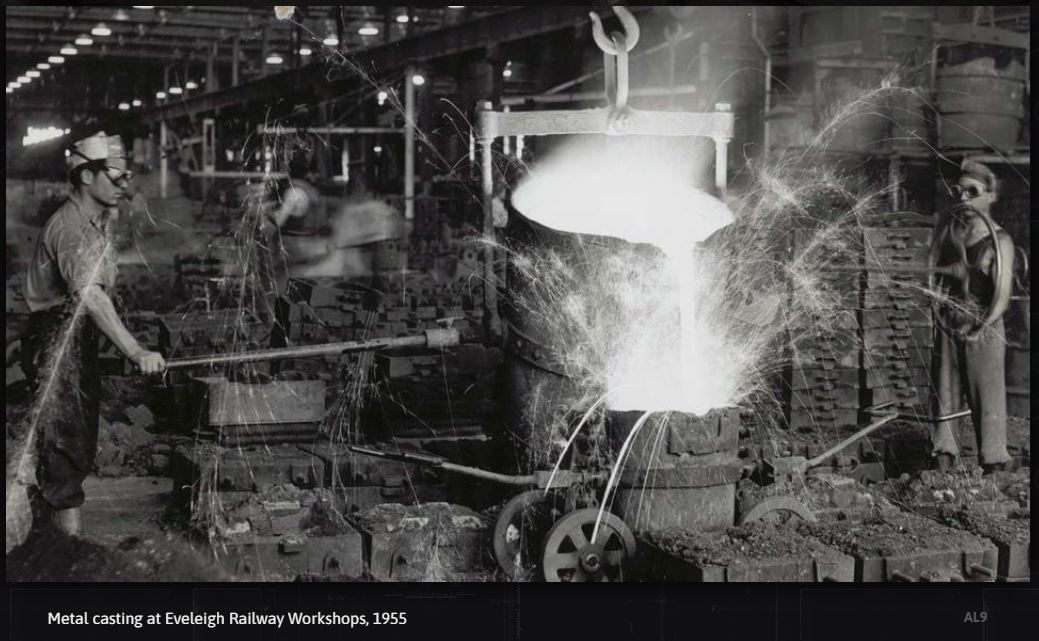

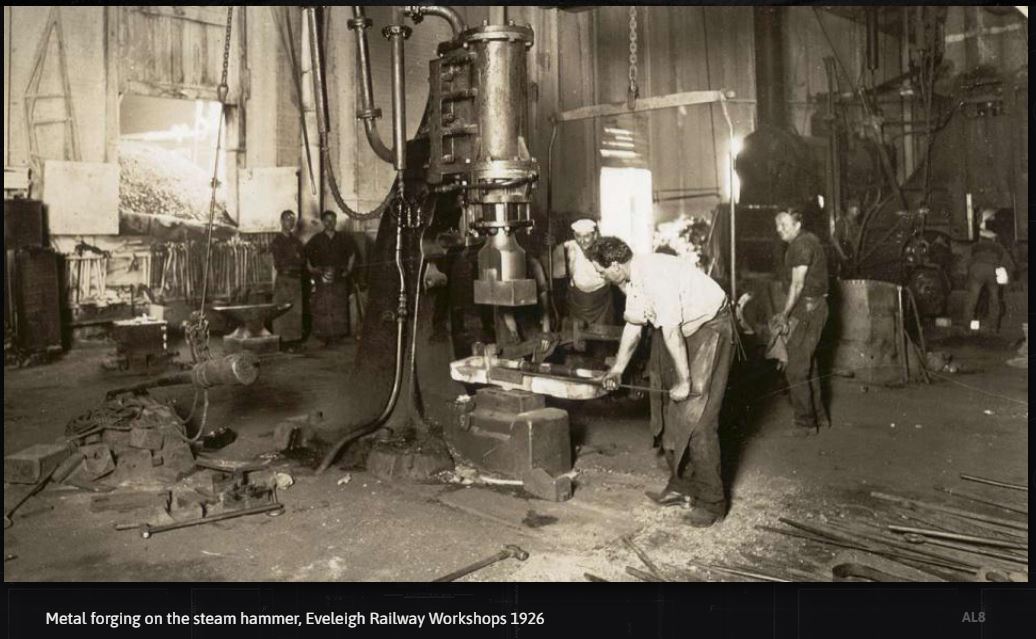

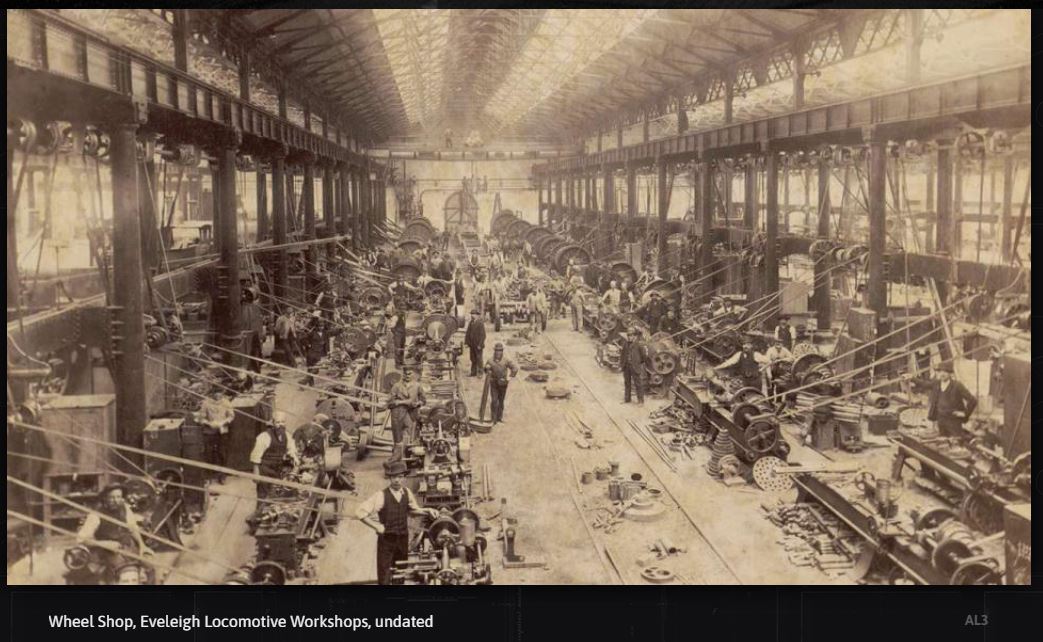

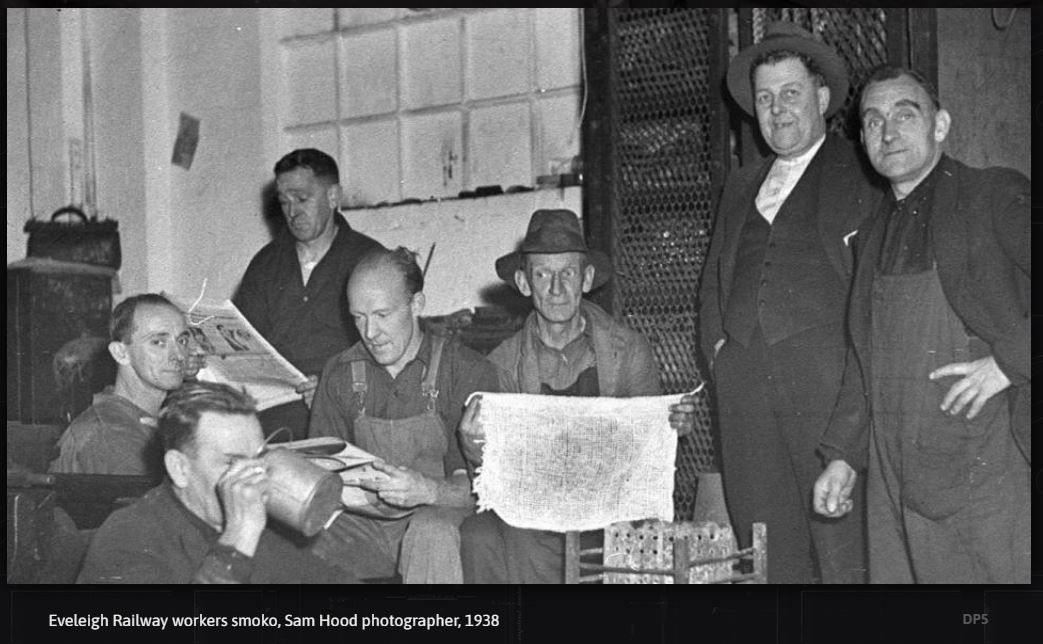

My great-grandfather was a boilermaker working at Eveleigh Railway Workshops making steam locomotives.

Evolution of Eveleigh – The Railway workshops | South Eveleigh Heritage

My father, Barry, was the original founder of BRH Steel Constructions in 1976 in the garage at home in Chester Hill. I remember spending time in the workshop alongside Dad, watching and learning. I was fascinated by the capability of steel, how it could be bent, rolled, and shaped into anything.

I was 16 years old when I signed up for my apprenticeship on 30 March 1995 in Metals and Engineering. I attended Mt Druitt TAFE as do all our apprenticeships to this day.

This business has grown from a one-man operation to a company that now employs up 25 people, of which 4-6 at any one time are apprentices learning their trade, therefore keeping the Metal Fabrication trade alive and growing.

Every job we take on is about providing a positive experience for our customers from the design, fabrication, and installation.

I believe in transparency and have a solid belief in being honest, trustworthy, and respectful. I feel that these qualities allow me to be an easy, approachable person which led to building great, sustainable relationships with builders within our industry.

“Everything we do, we do for our customers – our work starts and ends with them.”

What does the future hold…

We always have grand plans, but honestly, I just want to come to work and do what I love. I want to see my boys develop their own skills and find their niche in this business, I want to see my team grow and learn from the variety of work that comes through our doors. Everyone that works here has the capacity and the capability to become whatever they want to be in this business, and I hope that I can help them on that journey.

As for our customers, I love that I have been working with some of them my entire working life, it tells me that they trust and like working with my team and me. But I like that we are getting new businesses seeking our services, often by recommendation of existing clientele. Again, this tells me that what we are doing is right.

For my team, I encourage them to constantly look for ways to which we can improve our capability.

C36 Boiler Construction

Eveleigh - Ready to Roll

Eveleigh Locomotion Workspace

Eveleigh Workers with C3806 Locomotive

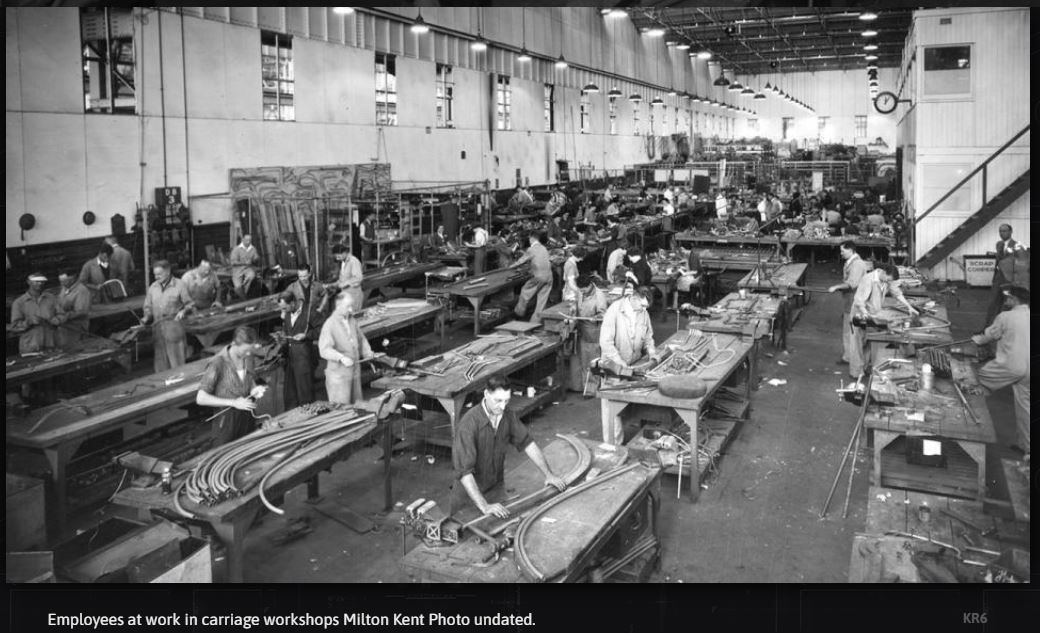

Eveleigh Workshop Floor

Eveleigh Workshop Locomotion Building

Eveleigh Workshop

Eveleigh Workshops

Forging Metal on Davy Press

Large Erecting Shop

Locomotive being hoisted in The Loco Shop

Machine Shop Eveleigh

Metal Casting at Eveleigh

Metal Forging on the Steam Hammer

Moulders on Driving Wheel

Wheel Shop Eveleigh

Workers at Smoko 1938